Creación y División de Curvas Inclinadas

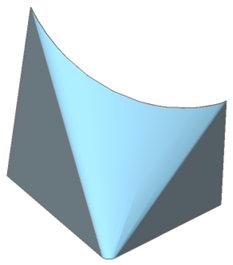

BricsCAD® permite crear o reconocer piezas de chapa metálica alabeadas con geometría curvilínea, que se pueden fabricar mediante plegado múltiple.

Procedimiento General para Crear una Pieza de Chapa Metálica con una Curva Inclinada

- Inicie el comando SMLOFT.

- Haz una de las siguientes cosas:

- Haga clic en el botón de la herramienta Crear pliegue solevado (

) en la barra de herramientas Chapa metálica .

) en la barra de herramientas Chapa metálica . - Haga clic en el botón de la herramienta Crear pliegue solevado (

) en la barra de la cinta Chapa metálica .

) en la barra de la cinta Chapa metálica . - Seleccione Crear recubrimiento de chapa metálica en el menú Chapa metálica.Se le solicitará: Seleccione dos secciones transversales:

- Haga clic en el botón de la herramienta Crear pliegue solevado (

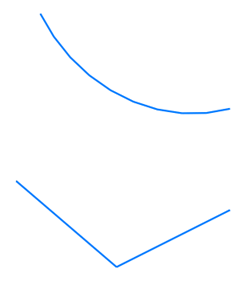

- Seleccione 2 entidades de perfil.

Se le solicitará: Establezca [Radio de redondeos/Espesor/Doblado único/Bridas con plegados] <Flanges with bends>:

Se le solicitará: Establezca [Radio de redondeos/Espesor/Doblado único/Bridas con plegados] <Flanges with bends>: - Pulse Enter para aceptar la configuración predeterminada.Se crea una vista previa de la pieza de chapa.Se le solicitará: Establecer [Radio de redondeos/Espesor/Doblado único/Bridas con dobleces/Espesar interior/Ambos lados/Espesar exterior]:

Note:

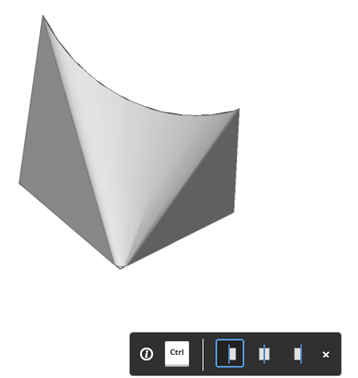

Note:Si el campo HKA de la barra de estado está activado, se muestra el widget Asistente de teclas de acceso rápido .

Pulse la tecla CTRL para elegir la posición del espesor de la pieza de chapa con respecto a los perfiles de origen: Engrosar por dentro, Espesar por ambos lados o Engrosar por fuera.

- Pulse Enter para crear la pieza de chapa.

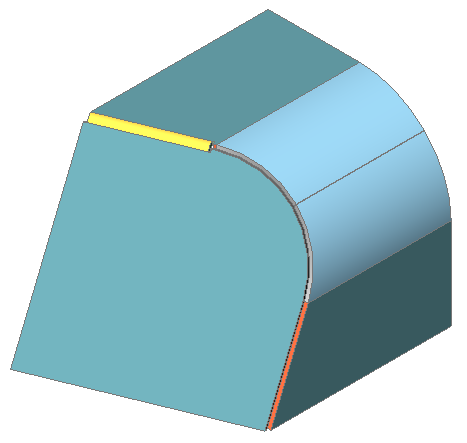

Si FEATURECOLORS está activado, puede distinguir entre las 2 pestañas (

Si FEATURECOLORS está activado, puede distinguir entre las 2 pestañas ( ) y el pliegue solevado (

) y el pliegue solevado ( ).

).

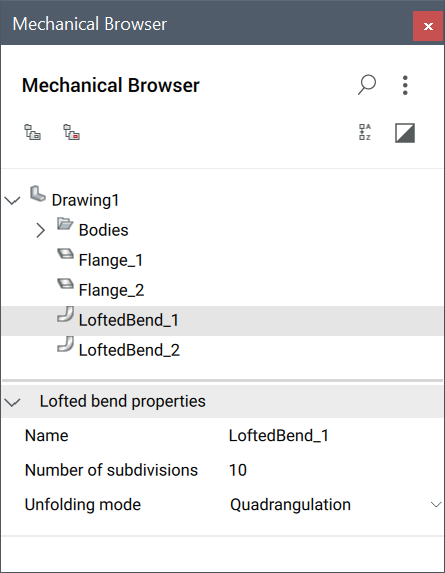

Las propiedades del pliegue solevado se muestran en el Navegador Mechanical:

Opcionalmente, seleccione la función de curva elevada para editar sus propiedades:

- Número de subdivisiones: el número de regiones planas en la representación desplegada de una entidad de pliegue solevado (cuanto mayor sea el número, más líneas de pliegue se agregarán a la vista desplegada para el pliegue relevado).

- Modo de desdoblamiento: la mayoría de las curvas alabeadas se pueden desplegar utilizando un algoritmo inteligente de teselación del Quad. Sin embargo, a veces puede producir resultados no óptimos. En tales casos, establezca esta propiedad en Triangulación para cambiar a un algoritmo más sencillo, que crea cuadrangulares en forma de triángulo.

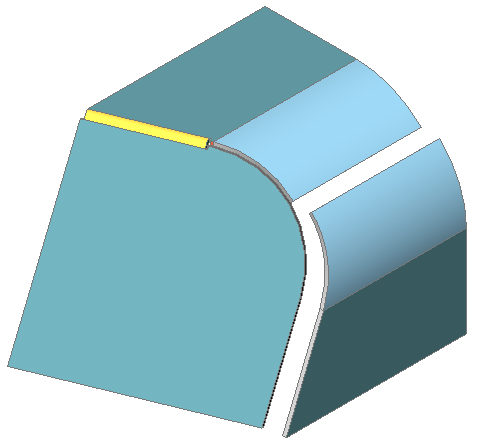

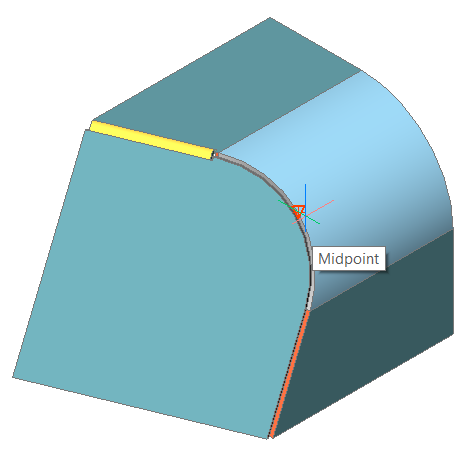

Para dividir un pliegue elevado

Los pliegues elevados se pueden dividir a lo largo de una línea en la superficie elevada en un punto arbitrario:

- Haz una de las siguientes cosas:

- Haga clic en la herramienta Dividir (

) en la pestaña de la cinta Chapa metálica .

) en la pestaña de la cinta Chapa metálica . - Seleccione Dividir en el menú .

- Escriba SMSPLIT en la línea de comando.Se le solicitará: Seleccione líneas o bordes para dividir la brida o [División inteligente/dibujar una nueva línea/opciones de selección (¿?)]

- Haga clic en la herramienta Dividir (

- Elija la opción dibujar una nueva línea.

- Especifique los puntos inicial y final de la línea en la pestaña seleccionada.

La curva inclinada está dividida. Si la unión de conexión está disuelta, puede mover libremente la parte separada.