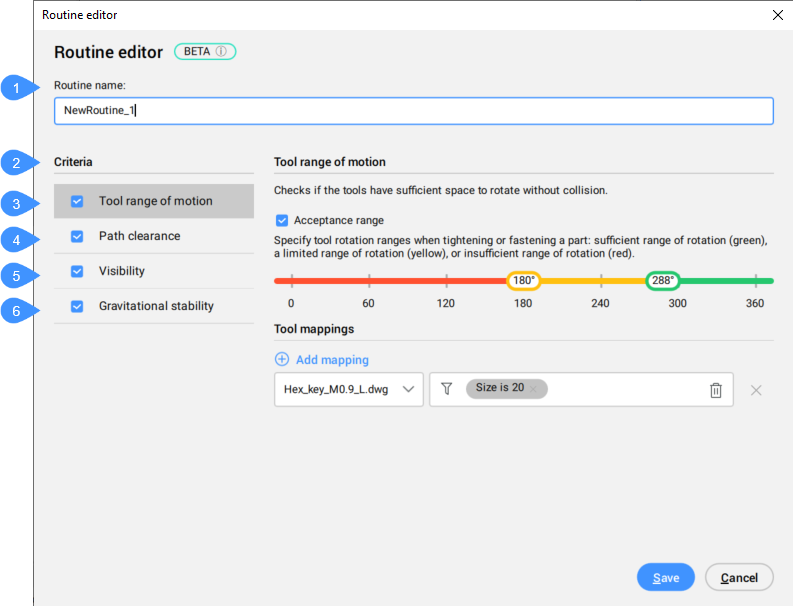

Routine editor dialog box

The Routine editor dialog box allows you to create criteria that will be taken in consideration in Assembly Inspect tool.

- Routine name

- Criteria

- Tool range of motion

- Path clearance

- Visibility

- Gravitational stability

Routine name

Specifies the profile name under which the rules are grouped.

Criteria

There are three category of criteria which will be taken in consideration for inspection of the assembly.

Tool range of motion

Evaluates whether tools have sufficient maneuverability space. For example, whether each fasteners have enough space to be handled with the specific tool.

- Acceptance range

- Specifies the tool rotation ranges when tightening or fastening a part: sufficient range of rotation (green), a limited range of rotation (yellow), or insufficient range of rotation (red).

- Tool mappings

- Allows you to add tool mapping to the existing ones defined with the Assembly Inspect Settings dialog box.

Path clearance

Evaluates if the parts can be easily added and removed at the current step without collision along the X, Y, and Z axes.

- Acceptance range

-

Specify the clearance ranges when a part is added or removed: the path is clear of obstacles (green), the path is partially restricted (yellow), or the path is blocked (red).

Visibility

Evaluates the visibility of the active parts from the user-defined viewpoints. The operator viewpoints are defined by the distance to the center of the assembly and the angle in the XY plane.

- Acceptance range

- Specify the visibility ranges for active parts: clear visible (green), partially covered (yellow), or invisible/obstructed (red).

- Add viewpoint

- Adds viewpoint for visibility check.

Gravitational stability

Evaluates the gravitational stability for each part of the current step in three ways: falling, sliding, and tilting. If parts are falling, sliding and tilting is not considered anymore.