Arkusz Blachy Właściwości Globalne i Właściwości Obiektów

Przegląd

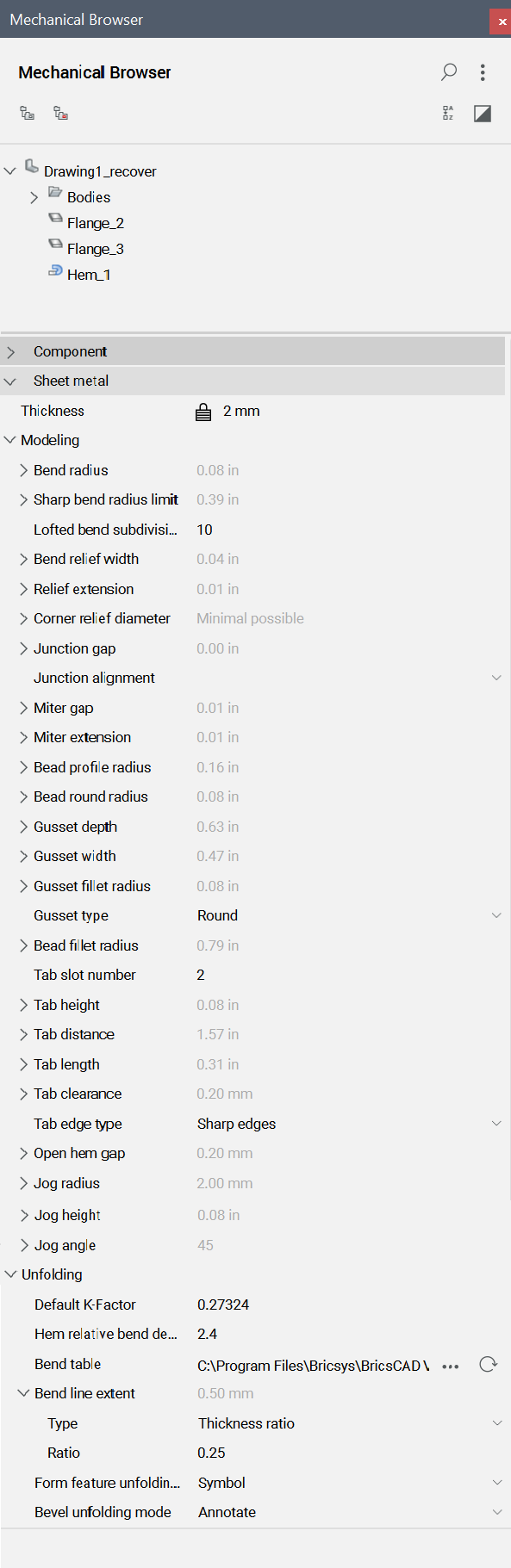

Funkcje arkusza blach i menu kontekstowe znajdują się w panelu Przeglądarki mechanicznej. Zobacz Przeglądarka mechaniczna dla Arkuszy Blach, aby zrozumieć ogólne zasady. W tym artykule opisano poszczególne właściwości i menu kontekstowe dla każdego typu węzła w panelu Przeglądarki mechanicznej.

Podczas pracy z częściami blaszanymi, kliknięcie węzła głównego w panelu Przeglądarka mechaniczna wyświetla właściwości całego rysunku. Czasami właściwości te są określane jako Globalny Kontekst arkusza blachy powiązany z rysunkiem: każda część arkusza blachy domyślnie współdzieli ten kontekst.

Dla danej bryły można przypisać kontekst local Arkusza Blachy dla danej bryły, co pozwala definiować części Arkusza Blachy o różnych parametrach projektowych, a ponadto zmieniać grubość części. Przed BricsCAD V21 wszystkie części w przestrzeni modelu musiały mieć tę samą grubość, co zmuszało użytkownika do rozłożenia części o różnej grubości na różne bloki lub komponenty. Scenariusze z wieloma importowanymi ciałami angażującymi ABKONWERTUJ i ABEKSPORTZŁOŻENIA również korzystają z tej nowej funkcji. Kolejną zaletą jest to, że lokalny kontekst arkusza blachy może zdefiniować własną tabelę gięcia.

Przełączanie kontekstu bryły na lokalny

- Wybierz korpus w panelu Przeglądarka mechaniczna.

- W sekcji Blacha przełącz Typ kontekstu z Kontekst globalny na Kontekst dla bryły.

Globalne właściwości blachy znajdują się w dolnej części Przeglądarki mechanicznej.

| Właściwości Globalne | Opis |

|---|---|

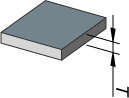

| Grubość | Globalna grubość materiału arkusza blachy.

|

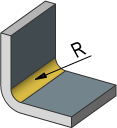

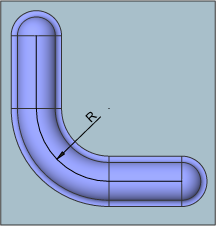

| Promień zagięcia | Domyślny promień elementów gięcia; można go również zmienić dla każdego gięcia.

|

| Limit dla ostrego promienia gięcia | Maksymalny promień gięcia uznawany za ostre (regularne) gięcie. Używany w poleceniach ABKONWERTUJ i ABSTWÓRZWYCIĘCIE do rozróżniania pomiędzy zwykłymi i wyciągniętymi zagięciami.

|

| Podpory zgięte wyciągnięte po profilach | Ustawia domyślną liczbę podziałów dla wyciągniętych zagięć. |

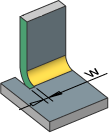

| Szerokość wycięcia na gięciu | Szerokość cięcia w pobliżu pojedynczego zagięcia.

|

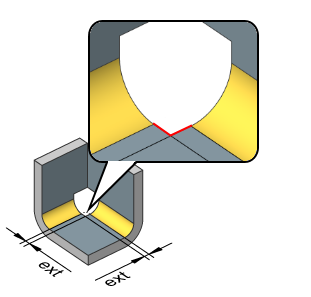

| Rozszerzenie wycięcia | Rozmiar zagięcia lub przedłużenia narożnika.

|

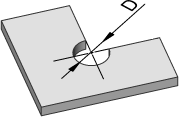

| Średnica wycięcia narożnika | Domyślna średnica okrągłego wycięcia narożnika. Typ: minimalna możliwa wartość lub wartość bezwzględna.

|

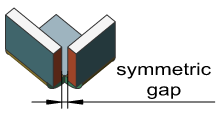

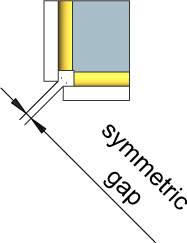

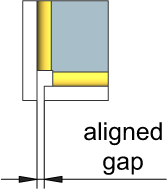

| Przerwa na złączu | Szczelina między 2 sąsiednimi wywinięciami.

|

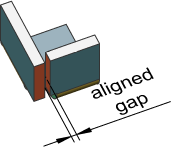

| Wyrównanie połączeń | Kontroluj wyrównanie powierzchni złącza z odpowiednimi narożnymi wycięciami powierzchni.

|

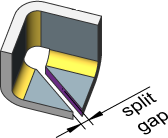

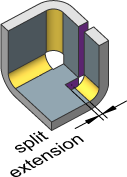

| Luka narożnika | Szczelina między grubymi powierzchniami kołnierza lub sąsiedniego zagięcia podczas rozszczepiania, patrz ABPODZIEL.

|

| Rozszerzenie ukośne | Kontrola głębokości cięcia sąsiedniego kołnierza w przypadku podzielenia kołnierza.

|

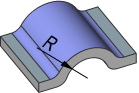

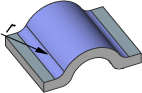

| Promień profilu tłoczenia | Promień narzędzia, które tworzy tłoczenie.

|

| Promień zaokrąglenia tłoczenia | Promień zaokrąglenia między wywinięcie a tłoczeniem.

|

| Promień zaokrąglenia tłoczenia | Promień zaokrąglenia krzywej kontrolnej żebra. Zobacz Praca z formą i Funkcjami Tłoczenia.

|

| Ilość zakładek | Określa numer slotu karty. |

| Wysokość zakładki | Określa wysokość zakładki.

|

| Odległość zakładki | Określa odległość zakładki.

|

| Długość zakładki | Określa długość zakładki.

|

| Prześwit zakładki | Określa prześwit zakładki.

|

| Typ krawędzi zakładki | Kontroluje typ krawędzi zakładki.

|

| Otwórz odstęp brzegu | Definiuje odstęp brzegu.

|

| Promień uskoku | Definiuje promień uskoku.

|

| Wysokość uskoku | Określa wysokość uskoku.

|

| Kąt uskoku | Określa wartość kąta uskoku. |

| Rozwijanie | Parametry dla rozwiniętej reprezentacji. |

| Domyślny współczynnik K | Współczynnik K dla promienia gięcia równego grubości. |

| Odliczenie względnego wygięcia krawędzi | Określa odjęcie zgięcia względem grubości używane podczas rozwijania elementów brzegu. |

| Tabela gięć | Wyświetla okno dialogowe Otwórz dla tabel gięć w formacie pliku CSV. |

| Wydłużenie linii gięcia | Kontroluje, jak daleko linia zgięcia wykracza poza granicę rozwinięcia (dozwolone są wartości zerowe i ujemne).

|

| Tryb rozwijania narzędzi formowania | Kontroluj wygląd cech kształtu w rozwiniętej reprezentacji.

|

| Tryb ukosowania | Sterowanie trybem rozkładania skosu (patrz artykuł Praca ze skosami).

|

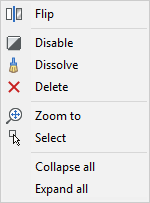

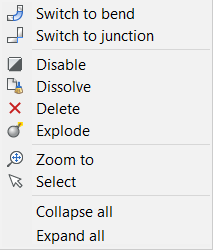

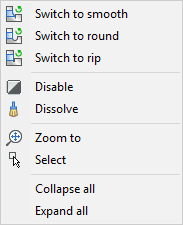

Kliknij funkcję prawym przyciskiem myszy, aby wyświetlić menu kontekstowe funkcji.

| Menu kontekstowe funkcji | Opis |

|---|---|

Wspólne narzędzia:

|

|

| Właściwości Wywinięcia | Kliknij prawym przyciskiem myszy element kołnierza:

Odwróć: zamiana boków wybranego kołnierza, tak aby powierzchnia odniesienia znajdowała się po przeciwnej stronie geometrycznej kołnierza. Ta operacja przesuwa kołnierz o jego grubość, aby zachować pozycję powierzchni odniesienia. |

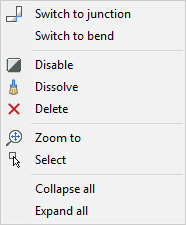

| Właściwości Gięcia | Kliknij prawym przyciskiem myszy element zgięcia:

|

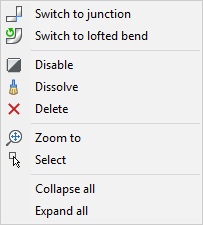

| Właściwości Wyciągniętego Gięcia | Kliknij prawym przyciskiem myszy element wyciągniętego gięcia:

|

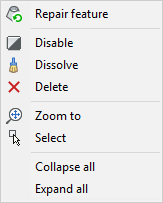

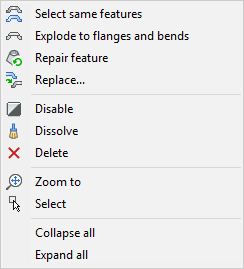

| Nieprawidłowy element gięcia | Kliknij prawym przyciskiem myszy nieprawidłowy element zgięcia:

Narzędzie naprawiania: naprawa nieprawidłowego elementu gięcia poprzez utworzenie elementu gięcia o odpowiedniej geometrii, jeśli to możliwe. |

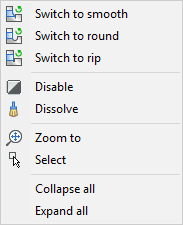

| Właściwości Wycięcia na Gięciu | Kliknij prawym przyciskiem myszy cechy wycięcia na gięciu:

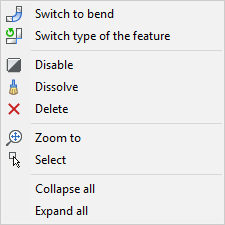

Przełącz na łagodne/U-kształtne/rowkowe: przełączenie wycięcia na gięciu na wybrany typ elementu. |

| Właściwości wycięcia narożnego | Kliknij prawym przyciskiem myszy element narożny:

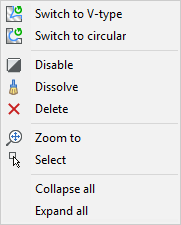

Przełącz na V-kształtne/okrągłe: przełączenie narożnego elementu wycięcia na wybrany typ elementu. |

| Właściwości Złącza | Kliknij prawym przyciskiem myszy funkcję łączenia:

|

| Właściwości Skosów | Kliknij prawym przyciskiem myszy funkcję ścięcia:

|

| Właściwości Formy | Kliknij prawym przyciskiem myszy funkcję formy:

|

| Właściwości Zakładki | Kliknij prawym przyciskiem na element zakładki:

|

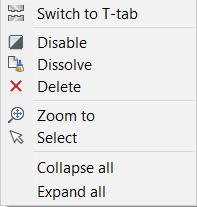

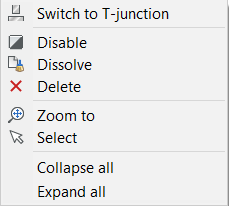

| Funkcja Złącze T | Kliknij prawym przyciskiem myszy funkcję Złącza T:

Zmień na T-zakładkę: konwersja funkcji T-Złącze na funkcję T-zakładkę. |

| Właściwości T-zakładki | Kliknij prawym przyciskiem myszy funkcję T-zakładki:

Zmień na T-złącze: konwersja funkcji T-zakładki na funkcję T-złącze. |

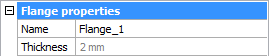

| Właściwości elementów | Opis |

|---|---|

| Właściwości wspólne: Nazwa: nazwa wybranego elementu blachy. Opcjonalnie wpisz nazwę funkcji. Domyślna nazwa elementu to typ elementu plus przyrost, na przykład Wywinięcie_1, Wywinięcie_2, .... |

|

| Właściwości Wywinięcia | Kliknij element kołnierza:

Grubość: bieżąca grubość. Wartość jest tylko do odczytu i jest równa właściwości grubości komponentu blachy. |

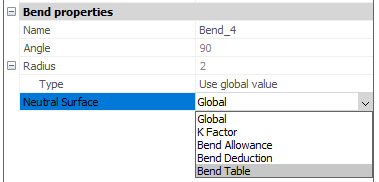

| Właściwości Gięcia | Kliknij element zagięcia:

|

| Wycięcie na gięciu | Kliknij element Wycięcie na gięciu:

|

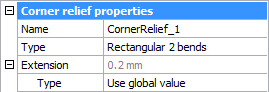

| Wycięcie narożne | Kliknij element wycięcia narożnego:

|

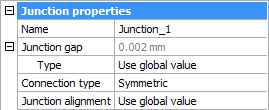

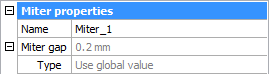

| Właściwości Złącza | Kliknij element złącza:

|

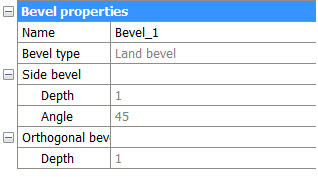

| Właściwości Skosów | Kliknij element skosu:

|

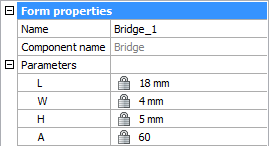

| Właściwości Formy | Kliknij element formy:

|

| Elementu skosu | Kliknij element skosu:

|